DustCount 900P

Special Pharma edition of the popular DustCount Product line. The sensor has been modified to have a higher sensitivity for Pharma type applications where concentrations are extremely low and may only last for a fraction of a second but must be detected accurately and immediately to protect the production batch and the operators of the equipment.

DustCount 900P Product Overview

Special Body strap to locate in the breathing zone

10 hour battery life

Wireless communications for management and data

Can be customized for special pure dust types such as coal and pharmaceuticals

Automated operation reduces the effort for the Hygienist & safety staff

Full range of detection & alarms allows one instrument to handle the job

IECEx Intrinsic safe approval for coal mining

DustCount Compliance and Certifications

Audible and visual alarms

Ease of cleaning between uses

Included PC software to control the device and analyse/graph data

App for Android smartphone or tablet allows in-field analysis and control

Offers many features to allow automation of sampling and real-time networking of results

DustCount 900P Features

Weighs 1 lb (.5kg), 4 x 5 inches clips on belt or in vest pocket

Minimum 12-hour battery life, special shift monitoring mode

On-board memory for 6+ months worth of data.

USB cable or Bluetooth wireless interfaces to PC or field device.

Self-adjusting air flow rate, no user action required

1L/min flow rate with +/- 5% accuracy

PM 2.5 environmental, PM 4 respirable, and PM 10 impactors

Settable detection and alarms for PEL, STEL, and TWA monitoring.

Maintenance alerts for battery, pump, filter, and impactor

Audible and visual alarms for worker exposure mitigation.

Data output in CSV files for NA and European formats, or Excel format.

DustCount 900P Sample Filter

Built-in cassette with a removable standard PTFE or PVC 25 mm filter.

Cassettes can be pre-loaded, pre-weighed and analysed by accredited labs

Filters can be selected for gravimetric analysis, or composition analysis.

Filters can be analysed using portable FTIR for silica content.

User can enter gravimetric coefficient information from filter analysis

Dust can be analysed and selectable dust types can be imbedded in the unit

Nanozen Desktop Software

Allows the user to connect to and control up to 128 DustCount units

Configure the DustCount date, time, mode of operation, sample frequency

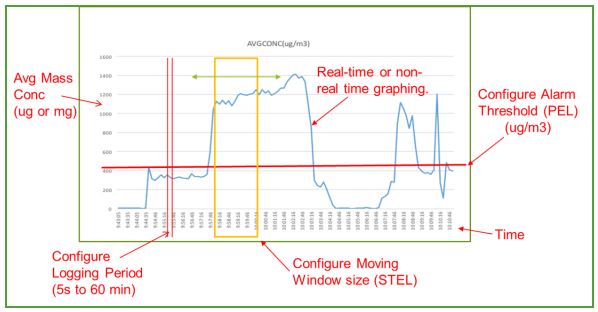

Set the alarm thresholds for PEL, STEL, and TWA

Set the start and stop times for sampling with shift management mode

Enter a gravimetric or dust related co-efficient for increased accuracy

Has a dashboard to monitor operational status, sample values, and alarm status

Download and save data to either .csv or native Excel format one sample per line

Generate and save graphs for mass concentration and particle size distribution data in .png format

Download and graph mass concentration and particle size distribution data in real-time

Observe PEL, STEL, and TWA in real-time graphs

Feature Descriptions

Direct Graphing

Enables a PC user to graph any 2 of the following 7 columns in the collected log data: Mass Concentration, Moving Window Average Mass Concentration, Count Concentration, Internal Temperature, Ambient Pressure and Battery State of Charge.

Moving Window Average

The mass concentration Moving-Window Average (MWA) is the average of a pre-set number of previous log mass concentration readings. The logging period set by the user plus the number of logs that are averaged determines the size of the Moving-Window in minutes.

Particle Distribution

Nanozen's DustCount combines the advantages of real-time dust monitoring with the ability to do the standard method, all in the industry's smallest and lightest optical particle counter. The DustCount also provides particle distribution on every sample.

Application Notes

Containment Verification

Using Nanozen’s DustCount to test Containment (FAT and SAT) for a Pharma Production line.

DustCount Consumables

Learn about consumables used with Dustcount, their use and recommended vendors and replacement schedules.

Factory Worker

Monitoring worker silica exposure to dangerous dust over an 8-hour shift in a typical factory setting.

In the Box

Laminated Quick-start guide in the lid

Calibration Certificate

DustCount Unit with cap

Installed cassette assembly including backing pad and sample filter

Impactor assembly of the customer’s choice (PM 2.5, PM 4 or PM 10)

USB stick containing documentation, UI software and How-To videos

Anti-static breathing tube with lapel clip

Lithium Ion battery with safety protection circuit for worry free air or ground transport

USB charger with overcharge protection

USB cable for data transfer to PC

HEPA filter, impactor oil & cassette removal key